Curious Kids is a show for teenagers of all ages. If you’ve gotten a matter you'd like an authority to reply, send it to curiouskidsus@theconversation.com.

How do you construct things like tunnels and bridges underwater? – Helen, age 10, Somerville, Massachusetts

As a toddler I discovered a Calvin and Hobbes comic strip This led me to one among my burning questions: How do they know what the load limit of bridges is? Calvin's father tells him (incorrectly): “They drive over it with bigger and bigger trucks until the bridge breaks. Then they weigh the last truck and rebuild the bridge.”

Several a long time later I’m a geotechnical engineer. This implies that I work on all construction projects that involve earth. Now I do know the actual answers to the questions people ask about infrastructure. Often, like Calvin's father, they think from the incorrect direction. Engineers don’t often determine the load limit of a bridge, but somewhat construct the bridge to support the expected load.

The same goes for one more query I hear once in a while: How do engineers construct things underwater? They don't often actually construct things underwater – as a substitute they construct things that find yourself underwater. That's what I mean by that.

Building underground, under water

Sometimes you construct underwater, actually underground. It's not concerning the water you see on the surface, but what surrounds the actual structure you're constructing.

If your construction project is surrounded by rock or earth on all sides, it is mostly known as an underground construction – even when there may be a layer of water above it and you possibly can't see the rest from above.

In underground mining, powerful Tunnel boring machines to excavate soil directly. This machine is commonly called a mole for good reason. Like the animal, it digs a tunnel that resembles a burrow by digging horizontally through the soil and removing the excavated material behind it. This method could be used successfully to construct a tunnel through the soil beneath a body of water, which might then be lined and reinforced.

Using this method, the engineers were able Construction of the tunnelfor instance, a railway tunnel under the English Channel connecting England and France.

University Archives and Special Collections at UMass Boston

Although modern machines are quite advanced, this construction method began about 200 years ago with the Tunnel shield. Originally these were temporary support structures that provided a protected space for the employees to dig. As the tunnel grew, latest temporary structures were built deeper. As experience increased, the designs became higher and higher, the shields were built to be mobile and eventually developed into the fashionable tunnel boring machine.

Building on dry land before moving in

Some structures will ultimately be surrounded by water and rest on a river or sea floor. Fortunately, engineers have a couple of tricks up their sleeves to construct bridges and tunnels whose components are in direct contact with the water.

Underground structures are dangerous and difficult to access. Dealing with water brings additional challenges. While soil and rock could be disregarded to create a stable opening, water will all the time seep in to fill any gap and should be continually pumped out.

People, materials and machinery don't really work well underwater either. People need a continuing supply of air. Concrete pouring is difficult underwater and a few materials only work on land. And because gas engines depend on air to operate, underwater equipment may be very limited.

Some minor tasks – aligning and connecting prefabricated tunnel sections or checking that nothing has been damaged by immersion – might be carried out underwater, but the majority of the development work is unlikely to be. Once the structure is in place, constant monitoring and assessment will happen underwater.

Since it’s fundamentally unimaginable to construct underwater, there are two options: either you construct outdoors after which move the constructing underwater, otherwise you temporarily convert the underwater site right into a dry site.

In the primary option, staff often construct parts of the structure on dry land after which sink them in place. For example, the Ted Williams Tunnel in Boston was inbuilt sections in a shipyard. Workers dredged the long run tunnel path in Boston Harbor, clearing mud and other debris out of the best way. They then placed the sealed segments along the prepared trench. After the segments were connected, they opened the ends of the segments to create an extended, continuous tube. Finally, the tunnel was covered with earth and rock. Very little of the development actually took place underwater.

In other cases, comparable to in shallow water, construction staff may have the ability to construct directly from the surface. For example, staff can drive sheet metal shore retaining partitions directly into the bottom from a barge without having to divert water.

Temporary removal of water

The second option is to eliminate the underwater problem completely.

Although it’s difficult to create a dry spot on the underside of a body of water, it has an extended history. After leading the sack of Rome in 410 AD, the Visigothic King Alaric died on his way home. To protect his magnificent tomb from grave robbers, Alaric's men had temporarily diverted an area river to bury him and his prey within the riverbed before the river overflows its banks again.

Digital Visual Library of the US Army Corps of Engineers, From

Nowadays, for such a project, one would Cofferdam: a brief, watertight enclosure that could be pumped dry to create an open and protected construction site. Once the world is enclosed and the water pumped out, you’re in the world of regular construction work.

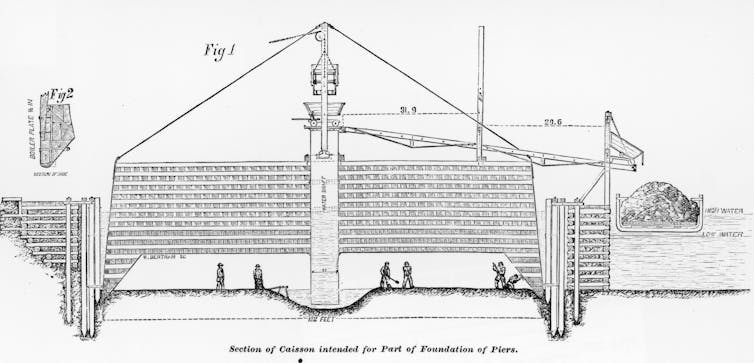

Using a caisson is one other technique to create a dry area on a construction site that will normally be underwater. A caisson is often a prefabricated and waterproof structure in the form of an upside-down cup that’s sunk into the water by a crew. They keep it pressurized to make sure that no water gets in. Once the caisson is on the underside of the body of water, the air pressure and pumps keep the location dry and permit construction staff to construct inside. The caisson becomes a part of the finished structure.

Photosearch/Getty Images

construction employee constructed the pillars of the Brooklyn Bridge with caissons. Although the caissons were structurally protected, the pressure difference affected many staff, including chief engineer Washington Roebling. He contracted caisson disease – higher often known as decompression sickness – and needed to resign.

Building underwater is a posh and difficult task, but engineers have developed several ways to construct underwater…often by not constructing underwater in any respect.

Hey, curious kids! Do you’ve gotten a matter you'd like an authority to reply? Ask an adult to send your query to CuriousKidsUS@theconversation.com. Please tell us your name, age and the town you reside in.

And since curiosity knows no age limit, adults can take part too. Let us know what interests you. We can't answer every query, but we'll do our greatest.

image credit : theconversation.com

Leave a Reply