Cheese is a comparatively easy food. It is comprised of milk, enzymes – proteins that may break down other proteins – bacterial cultures and salt. Many The cheesemaking process requires complex chemistrywhich may determine whether the cheese is soft and sticky like mozzarella or hard and fragrant like parmesan.

In fact, humans make cheese for about 10,000 yearsRoman soldiers got cheese as a part of their rations. It is a nutritious food that gives protein, calcium and other minerals. Its long shelf life allows it to be transported, traded and shipped over long distances.

I’m a Nutritionist on the University of Wisconsin who has studied cheese chemistry for the past 35 years.

In the United States, cheese is usually comprised of cow's milk. However, there’s also cheese comprised of the milk of other animals akin to sheep, goats, and even water buffalo and yaks.

Unlike yogurt, one other fermented milk product, cheesemakers remove whey – or water – to make cheese. Milk is about 90% water, while a cheese like cheddar lower than about 38% water.

Removing water from milk to make cheese creates a harder, firmer product with an extended shelf life, as milk spoils very easily. Before the invention of refrigeration, milk quickly turned sour. Cheesemaking preserved the nutrients in milk in order that it might be eaten weeks or months later.

How is cheese made?

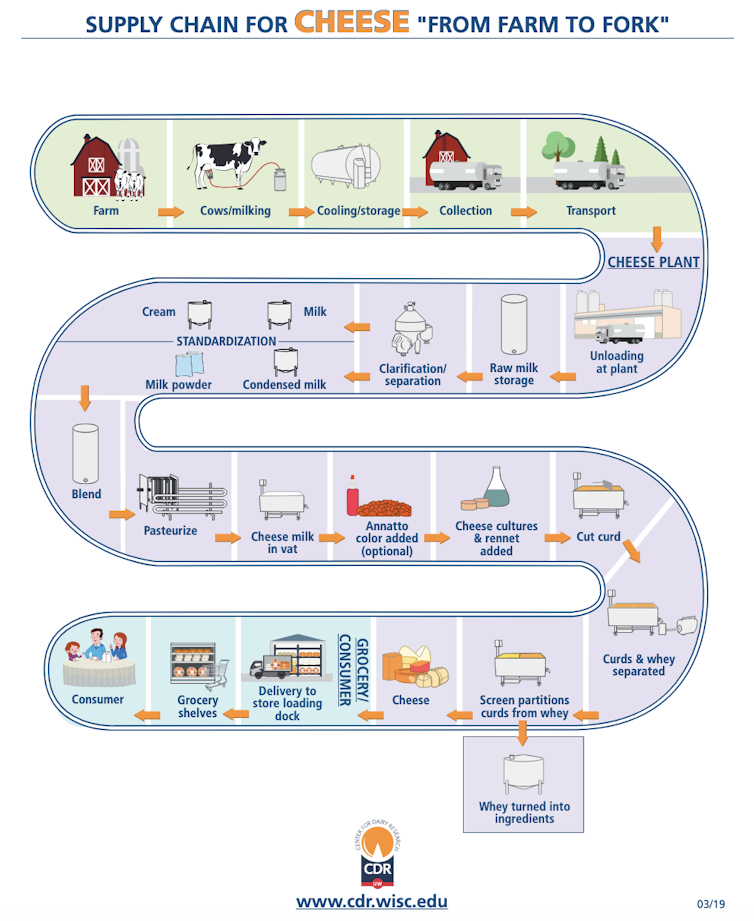

All cheese makers first pump milk right into a cheese vat and add a special enzyme called rennet. This enzyme destabilizes the proteins within the milk – the proteins aggregate and form a gelThe cheesemaker essentially transforms milk from a liquid right into a gel.

After 10 minutes to an hour, depending on the variety of cheese, the cheesemaker cuts this gel, often into cubes. Cutting the gel allows a number of the whey or water to separate from the curd, which is aggregated milk and appears like a yogurt gel. Cutting the gel into cubes allows a number of the water to flee from the freshly cut surfaces through small pores or openings within the gel.

The cheesemaker's goal is to remove as much whey and moisture from the curds as is essential for the actual recipe. To do that, the cheesemaker may stir or heat the curds, which releases whey and moisture. Depending on the variety of cheese, the cheesemaker will drain whey and water from the vat, leaving the curds.

UW Center for Dairy Research

For a harder cheese like cheddar, the cheesemaker adds salt to the curd while it remains to be within the vat. Salting the curd excretes more whey and moisture. The cheesemaker then packs the curds into molds or hoops – containers that help shape and hold the curds right into a block or wheel – and applies pressure to them. The pressure presses the curds into these hoops and so they bind together to form a solid block of cheese.

Cheese makers salt other cheeses, akin to mozzarella, by placing them in a Salt solution, also called brine. The block or wheel of cheese floats in a salt water tank for hours, days and even weeks. During this time, the cheese absorbs a number of the salt, which supplies it flavor and unwanted bacterial or pathogen growth.

UW Center for Dairy Research

Cheese is a living, fermented food

While the cheesemaker goes through all these steps, several essential bacterial processes are happening. The cheesemaker adds cheese cultures, bacteria they select to create certain flavors, at first of the method. Adding them to the milk while it remains to be liquid gives the bacteria time to ferment the lactose within the milk.

In the past, cheesemakers used raw milk, and the bacteria within the raw milk made the cheese sour. Today, cheesemakers use pasteurization, a mild heat treatment that destroys any pathogens present within the raw milk. However, this treatment implies that cheesemakers should add back some bacteria called starters – these “start” the fermentation process.

Pasteurization allows the cheesemaker to have a more controlled process, as he can add bacteria specifically as a substitute of the bacteria present within the raw milk. Essentially These bacteria eat (ferment) the sugar – Lactose – and produces lactic acid and other desirable flavors in cheese like diacetylthat smells like hot, buttered popcorn.

In some cheeses, these cultures remain energetic within the cheese long after it leaves the cheese vat. Many cheesemakers age their cheese for weeks, months, and even years to offer the fermentation process more time to develop the specified flavors. Aged cheeses include Parmesan, aged cheddar, and Gouda.

Wisconsin Dairy Farmers

Essentially, cheesemaking is a milk concentration process. Cheesemakers want their final product to contain the milk proteins, fat and nutrients without containing a lot water. For example, the most important milk protein obtained within the cheesemaking process is is casein. Milk can have a casein content of around 2.5%, but a finished cheese like cheddar can have around 25% casein (protein). So cheese comprises many nutrients, including protein, calcium and fat.

Endless possibilities with cheese

There are Hundreds of various varieties Cow's milk cheese is made everywhere in the world and so they all start with milk. All of those different varieties are made by adapting the cheesemaking process.

For some cheeses, akin to Limburger, the cheesemaker rubs a smear – an answer containing various sorts of bacteria – onto the surface of the cheese in the course of the ripening process. For other cheeses, akin to Camembert, the cheesemaker places the cheese in an environment (akin to a cave) that encourages mold growth.

Others like bandaged cheddar are wrapped in bandages or covered with ash. Applying a layer of ash to the surface of the cheese protects it from excessive mold growth and reduces moisture loss through evaporation. This produces a harder cheese with a stronger flavor.

Dairy Farmers of Wisconsin

Over the last 60 years, cheesemakers have found out how you can select the fitting bacterial cultures to create cheese with specific flavors and textures. The possibilities are infinite and there are not any limits to the cheesemaker's imagination.

image credit : theconversation.com

Leave a Reply