Fusion energy has the potential to be an efficient clean energy source due to its reactions incredibly large amounts of energy. Fusion reactors aim to breed what happens on Earth within the core of the sunwhere very light elements fuse and release energy. Engineers can use this energy to heat water and generate electricity via a steam turbine, however the path to fusion isn’t entirely straightforward.

Controlled nuclear fusion has several benefits in comparison with other energy sources for generating electricity. On the one hand, no carbon dioxide is produced throughout the fusion response itself. There is not any risk of a core meltdown and the response doesn’t produce long-lived radioactive waste.

I’m a Nuclear engineer who studies materials that scientists could use in fusion reactors. Fusion occurs at incredibly high temperatures. To at some point make nuclear fusion a viable energy source, reactors should be built from materials that may withstand the warmth and radiation produced by fusion reactions.

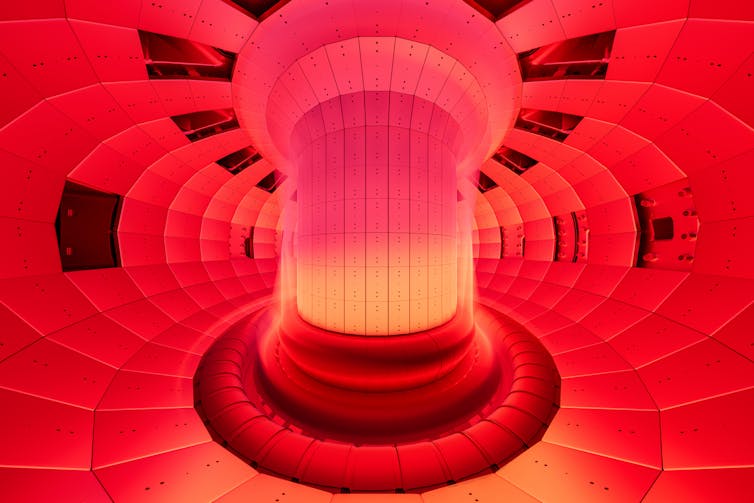

xia yuan/Moment via Getty Images

Challenges with fusion materials

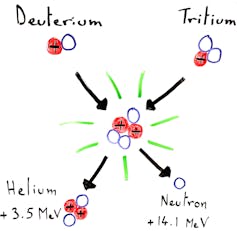

A fusion response can fuse multiple forms of elements. The one preferred by most scientists is Deuterium plus tritium. These two elements are most probably to fuse at temperatures that a reactor can maintain. This response produces a helium atom and a neutron, which transport many of the energy of the response.

Sophie Blondel/UT Knoxville

Humans have successfully created fusion reactions on Earth since 1952 – some even in theirs garage. But the trick now’s to make it price it. You must get more energy out of the method than you spend money on triggering the response.

Fusion reactions occur in a single highly regarded plasmaThis is a gas-like state of matter, but consists of charged particles. The plasma must remain extremely hot – over 100 million degrees Celsius – and condensed all through the response.

To keep the plasma hot and condensed and create a response that may proceed, special materials are required for the reactor partitions. You also need an inexpensive and reliable source of fuel.

While deuterium may be very common and is obtained from water, tritium may be very rare. A 1 gigawatt fusion reactor is designed to burn 56 kilograms of tritium annually. But the world only has about 25 kilograms of tritium commercially available.

Researchers must find alternative sources of tritium before fusion energy can get off the bottom. One possibility is that every reactor produces its own tritium via a system called “tritium.” Breeding cover.

The brood cover forms the primary layer Plasma chamber Walls and comprises lithium, which reacts with the neutrons produced throughout the fusion response to form tritium. The blanket also converts the energy carried by these neutrons into heat.

Fusion devices also need a diverterwhich removes the warmth and ash generated throughout the response. The divertor helps maintain reactions for longer.

These materials can be exposed to unprecedented levels of warmth and particle bombardment. And there are currently no experimental facilities to breed these conditions and test materials in a real-world scenario. The focus of my research is due to this fact on closing this gap using models and computer simulations.

From the atom to the whole device

My colleagues and I are working on developing tools that may predict how the materials in a fusion reactor erode and the way their properties change when exposed to extreme heat and high levels of particle radiation.

Irradiation may cause defects to form and grow in these materials, affecting their ability to answer heat and stress. We hope that government agencies and personal firms can use these tools to design fusion power plants in the longer term.

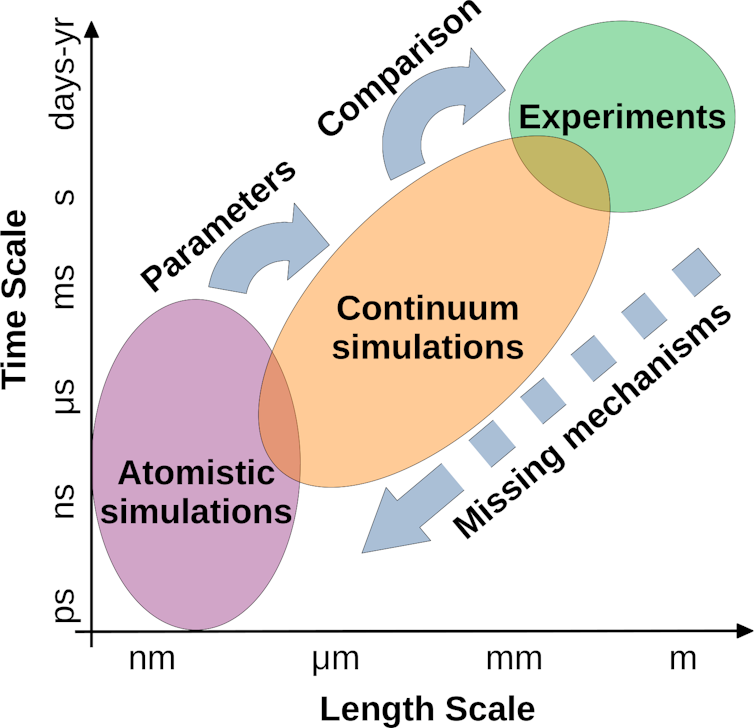

Our approach, called Multiscale modelingis to review the physics of those materials over different time and length scales using a spread of computational models.

We first investigate the phenomena occurring in these materials on the atomic level through precise but expensive simulations. For example, a simulation could examine how hydrogen moves in a cloth during irradiation.

From these simulations we consider Properties comparable to diffusivitywhich tells us how far the hydrogen can spread through the fabric.

We can integrate the knowledge from these atomic-level simulations into more cost effective simulations that examine how the materials react on a bigger scale. These large-scale simulations are more cost effective because they model the materials as a continuum relatively than considering each individual atom.

The atomic-scale simulations could take weeks to finish Supercomputerwhile the continuum will only last a couple of hours.

Sophie Blondel/UT Knoxville, adapted from https://doi.org/10.1557/mrs.2011.37

All of this computer modeling work is then compared with experimental results from laboratories.

For example, if one side of the fabric comprises hydrogen gas, we would like to know how much hydrogen escapes to the opposite side of the fabric. If the model and experimental results agree, we will have faith within the model and use it to predict the behavior of the identical material under the conditions we’d expect in a fusion facility.

If they don't agree, we return to the atomic-level simulations to look at what we missed.

Furthermore, we will Couple the larger scale material model with plasma models. These models can tell us which parts of a fusion reactor are hottest or subject to essentially the most particle bombardment. From there we will evaluate further scenarios.

For example, if an excessive amount of hydrogen leaks through the fabric during operation of the fusion reactor, we would recommend making the fabric thicker in certain places or adding something to trap the hydrogen.

Designing recent materials

As the seek for industrial fusion energy continues, scientists must develop more resilient materials. The field of possibilities is vast – engineers could make multiple elements together in some ways.

You could mix two elements to create a brand new material, but how do you understand what the right ratio of every element is? And what if you should try mixing? five or more elements together? It would take far too long to run our simulations for all of those possibilities.

Luckily, artificial intelligence is here to assist. By combining experimental and simulation results analytical AI can recommend mixtures which might be most probably to have the characteristics we’re on the lookout for, comparable to: B. Heat and stress resistance.

The goal is to scale back the variety of materials an engineer would have to supply and experimentally test, saving money and time.

image credit : theconversation.com

Leave a Reply