In 1950, global plastic production was around 2 million tons. There at the moment are about 400 million tons – a rise of just about 20,000%.

As a fabric, it has apparently unlimited potential. Plastic is inexpensive to supply while they’re light and robust. The applications range from food and beverage packaging to clothing and health care.

When a plastic article ends its useful life, it may well take an extended time for it to decompose 500 years in some cases. Even then, the plastic pieces don’t completely disappear – as a substitute, they collapse into and smaller parts and eventually turn into microplastics That ends in The soil through which we grow food, the water we drink and the air we breathe.

Research has connected this microplasty Health problems Like diabetes, heart disease and low male fertility.

For years, local governments and manufacturers have depend on recycling in response to the buildup of plastic waste. Despite their efforts to sort and separate value materials, most plastics still find yourself on landfills – or worse in green rooms and waterways.

According to the US environmental protection authority, the The total recycling rate for plastics is 8.7%. About a 3rd of the milk mugs and plastic bottles are recycled – the next rate than other plastic types.

Since plastic is used so often, it’s becoming increasingly necessary to seek out latest ways to administer and recycle plastic waste. Plastic waste pyrolysis is a technology that might help solve this problem.

This is a comparatively latest technology, so researchers still have limited knowledge of the pyrolysis process. As an analytical chemistWe strive to grasp the composition of complex mixtures, especially latest creations from sources equivalent to plastic waste pyrolysis.

What is plastic pyrolysis?

Plastic pyrolysis is a chemical process through which the plastics are chemically broken down into other molecules by raising the plastic to extremely high temperatures within the absence of oxygen.

Alexander Kaplitz and Kevin A. Schug

In contrast to traditional plastic recycling, Theoretically, pyrolysis just isn’t limited for certain sorts of plastic. It could possibly be brought on by a lot of them, although the present technology is proscribed to some species – polyethylene and polypropylene utilized in food containers and bottles.

Plastic pyrolysis could due to this fact help to administer the waste from consumer goods equivalent to plastic bags, bottles, milk jugs, packaging materials, wet wipes and even rejected children's toys. Pyrolysis also can Treat more complex plastic waste Like tires and thrown away electronics, although fixed waste traders and recyclers avoid certain plastic types in pyrolysis, equivalent to polyvinyl chloride – or PVC, which can be found in pipes and roof products – and polystyrene which can be utilized in packaging, equivalent to These can create harmful by -products.

During pyrolysis, the plastic polymers are divided into smaller molecules, which ends up in the production of liquid oil. Methan, propane and butanAnd char.

Char is the firm deficit at the top of the pyrolysis process. It may be used As carbon -rich material For various applications, including adding to the bottom to make it healthier for agriculture, it increases the soil moisture and the pH value, which advantages the nutrient absorption. Char also has the flexibility to achieve this absorb harmful carbon gases from the airWhich might help prevent climate change.

Char's principal party is used whether it is used an excessive amount of, it may well Increase the ground alkalitywhat plant growth can hinder.

https://www.youtube.com/watch?v=E5EEAH73UW

How pyrolosis works

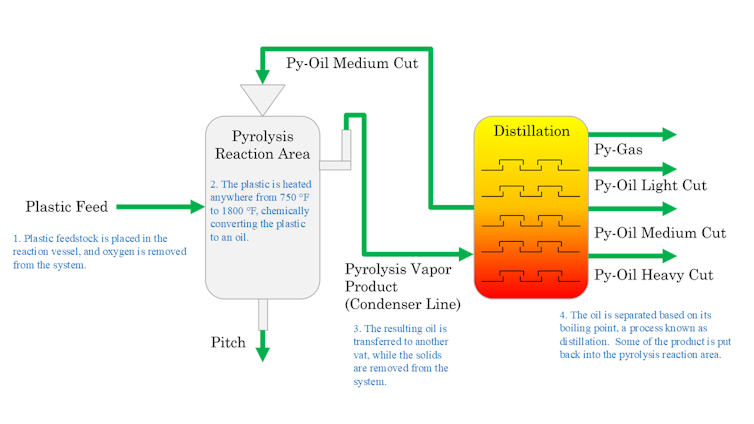

The plastic pyrolysis process typically includes several necessary steps.

In step one of pyrolysis, Community recyclers collect plastic waste and clean it to remove contamination. The plastic is then crushed into smaller pieces to facilitate the pyrolysis process. In contrast to traditional recycling, it needs Only minimal sorting.

Chemical recyclers who operate pyrolysis plants 600 to 1,600 degrees Fahrenheit (315 to 871 degrees Celsius). Without oxygen, plastics within the reactor don’t catch fire and emit vapors within the air. Instead, this high -temperature environment signifies that the plastic polymers result in it Brush into smaller hydrocarbon molecules. These smaller molecules may be further refined.

The hot temperature transforms some molecules into vapors that condense into liquid oil. Chemical firms can further refine this oil in an effort to use it as a fuel or as a raw material to supply other chemicals or plastics.

In addition to liquid oil, the pyrolysis process creates natural gases equivalent to methane, ethan, butan and propane. Pyrolysis operators then record these gases and might sometimes be a source of energy for Make the pyrolysis reactor with Or other industrial processes.

BASFPresent CC BY-NC-ND

Advantages of pyrolysis

With effective execution, plastic pyrolysis offers several benefits.

By expanding the recycling via only plastic bottles and milk mugs, pyrolysis could reduce the quantity of plastic waste pollution that ends on landfill and oceans.

In addition, it may well help convert plastic waste into usable products Lower production needs For latest plastics manufactured from petroleum hydrocarbons. The by -products could possibly be utilized in recycled plastics.

Some researchers also test pyrolysis oils to find out whether or not they can use them as a substitute of gasoline Fuel. The gases generated during pyrolysis may even generate energy that drives the pyrolysis reactor, which makes the method more self-supported and reduces the necessity for external energy sources.

Around 15% to twenty% of pyrolysis products are currently recycled into latest propylene and ethylene. While most – about 80% to 85% – becomes a diesel fuel, hydrogen, methane and other chemicals.

While plastic pyrolysis has a certain promise, it also faces challenges. The costs The establishment and operation of pyrolysis systems is high. How profitable the method is will depend on the supply of suitable plastic waste, market demand for the oils produced and the energy and personnel costs required for the operation of the reactor.

Another problem is quality control. Most plastic types may be subjected to pyrolysis, but different plastics generate oils with different chemical make -ups. Scientists must understand the composition of those oils before the industry can determine which plastic types should concentrate and the way any oil can create latest materials.

Alexander Kaplitz and Kevin A. Schug

Researchers like us on the University of Texas in Arlington and our international colleagues study latest chromatography-based, based chromatography Oil separation techniques This can successfully discover some sorts of pyrolysis oils. Chromatography is that Process of separation of components in a combination By giving them through a stiff material.

Various components within the mixture are interested in different dimensions by this material. So you allow the chromatography system at different times that separates it from one another.

With more research on efficiency and technological advances in technology to scale pyrolysis, this technology could possibly be a part of a sustainable solution for plastic waste management. In the meantime, pyrolysis is now used with A report estimates The marketplace for pyrolysis systems in 2024 of $ 40 billion and predicts that it’s growing to 1.2 billion US dollars by 2033.

image credit : theconversation.com

Leave a Reply