While you're driving, you're probably considering more about your destination than concerning the road surface you're driving over. However, constructing roads requires quite a lot of engineering feats, from developing the proper pavement materials to using heavy equipment to put them. The higher they’re built, the longer the roads last and the less construction delays drivers should endure.

I’m an engineer who conducts materials research used on the street area. Scientists in my field are working to develop materials that could make roads stronger and longer lasting.

Road materials

What are roads really made from? The easy answer is that they’re made from typical material Building materials comparable to aggregates – soils and rocks – as well Asphalt binder And Portland cementwhich act like glue and stick every thing together.

Asphalt binder is refined from crude oil. Refineries first extract gasoline, kerosene and oil from crude oil, and what’s left on the bottom becomes asphalt. Portland cement is produced from various ingredients including limestone, sand, clay, silica and aluminum oxide.

Engineers compact the asphalt binder and aggregate mixture at an elevated temperature of about 150 degrees Celsius, which glues the aggregates together to form the ultimate product Asphalt, concrete.

If they use Portland cement as a substitute of asphalt binder to connect the aggregates together, engineers say Cure the cement and aggregate mixture with water a process called hydration.

Hydration binds the cement to the aggregates to provide what’s referred to as the product Portland cement concrete, stronger. This process doesn’t require external heating.

Pavement structure

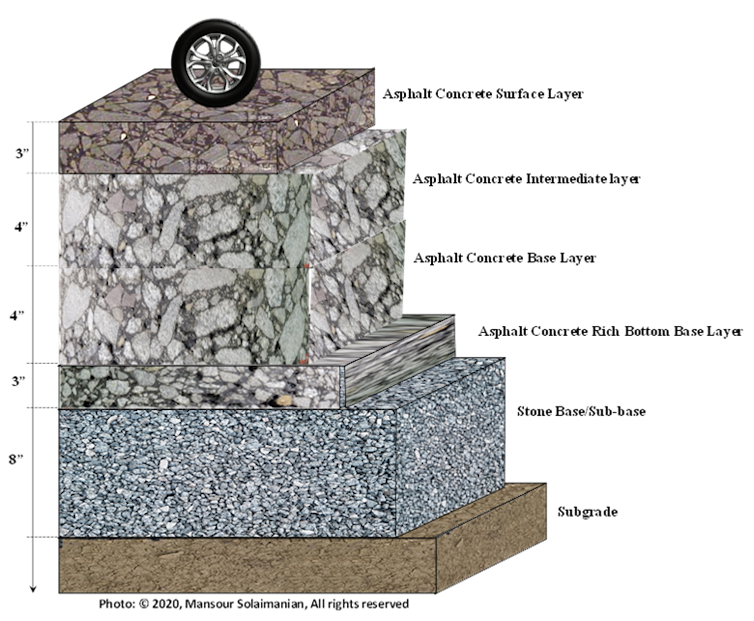

Asphalt concrete Pavement structure typically consists of three essential layers: the bottom layer, the intermediate layer and the surface layer.

Mansour Solaimanian

Engineers call the present soil on which the sidewalk runs underground. A brand new layer of unbound earth and stones is placed on the subsoil, whereby the aggregates usually are not glued together. This is known as a subbase or unbound aggregate base.

The base course can consist of either stones packed together without binder or a mix of stone and asphalt binder.

Once the road builders have created the bottom, it’s time to construct the asphalt concrete layers: the bottom layer, the intermediate layer and the surface layer. All of those layers contain the aggregates—the pieces of rock and sand—which are bonded in some strategy to the asphalt binder.

Engineers determine what number of layers to construct and the way thick each layer must be by determining how much traffic will travel over the road. The more traffic, the thicker the surface must be. For example, on interstate highways Depth of layers together could possibly be 20 inches (51 centimeters) or more.

Mansour Solaimanian

Build a powerful road

The road builders bring the fabric onto the road with one Asphalt paving machine known as a finisher. An operator operates the paver, which takes the fabric from a truck and puts it on the road. Thereafter, Heavy duty wheels Compact it, make it stable and prepare it for vehicles.

To ensure a stable and long-lasting road, engineers first select one of the best surface or location on which to construct the surface. If the subsoil is just too weak, the road can crack and fail – even when one of the best materials are used for the surface.

Mansour Solaimanian

First, the road builders compact the subsoil with rollers. Once they’ve compacted the subsoil, they place the aggregates directly on the subsoil and compact them. This aggregate carrier on the subsoil forms a stable foundation for the asphalt layers.

If the road builders don't use the proper materials, or don't put them together appropriately, or don't design the pavement structure for the expected traffic, the road can suffer this Cracks, ruts and failure.

Cracks occur either at extremely low temperatures or when heavy trucks and buses are repeatedly driven over on the road. Ruts, i.e. clear impressions within the road surface, occur under heavy trucks or at road intersections, especially in summer heat.

Potholes are a serious road problem that you just've probably seen before. They often occur within the spring after water trapped within the pavement freezes over the winter after which melts within the spring. This melting process weakens the road and makes it more fragile. When vehicles drive over them, potholes can form.

Mansour Solaimanian

Mansour Solaimanian

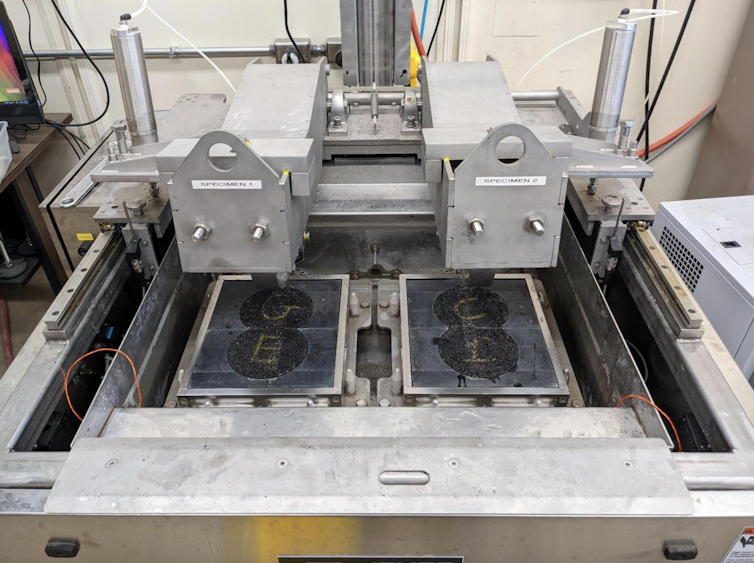

Before the road is built, the materials are tested within the laboratory to make sure they’ll withstand the stresses of traffic and the environment.

Mansour Solaimanian

Engineers within the lab subject the pavement materials to each freezing and extremely popular temperatures to make sure they’ll withstand every kind of weather. They also expose the paving materials to water to make sure that the materials don’t disintegrate during rain or flooding.

At the Penn State University Highway LaboratoryMy team tests asphalt mixtures to which we now have added so-called modifiers. These include special polymers and fibers that would make the road stronger.

Next time you're out and about, do not forget that it takes loads of engineering and tremendous teamwork smooth road surface You drive on.

image credit : theconversation.com

Leave a Reply