If you’re a frequent flyer, you will likely wait on the airport to attend somewhere on a winter trip when the voice of an airline's voice canceled the intercom that there can be a slight delay while the plane is lit. But how does this process actually work and why is it needed?

As a Mechanical engineer If you examine frost growth and water droplets on surfaces, I appreciate the importance of leveling levels. In fact, Deicing is a vital security step that the airlines run on winter days, as snow and ice can influence the physics of flying.

Why Deice?

In short, Deicing is vital because snow and ice will be on aircraft wings Reduce the buoyancy by as much as 30%. The vertical upturn, which holds a level within the sky. It is generated when air flows over the wings of an aircraft.

Ice and snow can change how air flows over the wings, which may influence a pilot's ability to maneuver and control the aircraft. It may also increase the stand speed, which just isn’t good either. The stable speed is the minimum speed that an aircraft must create enough buoyancy to maintain it within the air.

In addition, ice cream can break off on the wings and possibly damage a number of flaps on the wings or an engine. Unnecessary to say that the declaration has turn out to be an indispensable a part of flying, especially within the winter months.

Orchidpoet/E+ via Getty pictures

Disassemble chemicals

Most persons are conversant in the chemical deicers which might be used on streets within the winter months. However, the salts in these products will be corrosive, in order that they should not utilized in airplanes.

Airplanes Deicers consist of a A water -based solution of glycol – a colorless, odorless organic liquid – mixed with different additives. These additives can contain a thickener. a substance that stops corrosion; A Tenside that reduces the surface tension; A flame retardant and a dye.

Glycoles are superb at reducing the freezing point of the water, which makes it tougher to freeze water or remain frozen on surfaces. Propylene glycol and ethylene glycol are the 2 most regularly used types, typically Make 30% to 70% of the gain solution.

CACYCLE/WIKIMEDIA CommonsPresent CC BY-SA

For years, only ethylene glycol has been utilized in Deicers as a consequence of its low costs. However because Propylene glycol is less toxic to wild animals and folks, its introduction by business airlines steadily grown Since the Eighties.

How does the gap process work?

Use airlines Four standard liquid types When disappointing airplanes. These liquids have different viscosities – viscosity is a measure of the fluid resistance to the flow – and the holding times which might be so long that the liquid protects the extent in the course of the snow or icing conditions.

https://www.youtube.com/watch?v=HXZMJGNZNYE

In the United States, airlines normally use a two -stage process before flying. First, perform a deicing with a heated liquid or a heated solution of type I liquid and water.

Deisen removes existing ice and snow from the wings of the aircraft, which is why the airlines often Heat the Deic fluid too round 140 to 150 degrees Fahrenheit (60 to 66 degrees Celsius) before use.

Type -i fluids are the thinnest of the deis fluids and are sometimes red or orange. They are the simplest to distribute on the surface of an aircraft because they’ve the bottom viscosity. Since they’re thin enough to flow from an airplane if it just isn’t moving or slowly moving, they will be applied to any plane.

As a result, you furthermore mght have the shortest stop times, which are sometimes lower than 20 minutes depending on the weather conditions. However, these holding times varyAnd will be lower than five minutes for snow if the skin air temperature is below 14 f (minus 10 ° C).

Next, the ground teams normally carry an anti-Icing fluid on the aircraft. Type II or Type IV. Anti-Icing solutions are used to stop the long run accumulation of snow and ice on the wings of the aircraft.

Type II and Type IV liquids contain thickeners that increase their viscosity. These thickeners enable the liquid to remain on the plane longer to melt frost or ice cream. This means longer holding times – Often greater than half-hour for snow – however it also signifies that the plane has to attain a better speed to scissue or drag the liquid.

As soon because the liquids of Type II and IV normally stay on the plane until the aircraft stairs down the outlier in the course of the output. Until then, it has gained enough speed to generate the shear force required to remove the liquid from the extent. Type II liquids are a transparent or pale straw color, while the fluids of type IV are generally green. Inclusion of a coloured dye helps the ground team to obviously see which parts of the extent have been coated and which areas still need application.

Type III liquids should not that common anymore. They are formulated to chop off at lower speeds and due to this fact sometimes use in small commuter aircraft, since these planes don’t normally go as quickly as business jetliners.

Environmental effects of the frustration

Environmental considerations are also a vital a part of the frustration. Glycole require lots of oxygen for organic, what can Exhaustion of dissolved oxygen in streams or lakes. This in turn can threaten water life, resembling fish and other organisms that need dissolved oxygen to breathe.

In addition, ethylene glycol is poisonous for wild animals, i.e. the Environmental protection authority demands airports Monitoring of your rainwater outflow. For this reason, most airports collect and Treat rainwater outflow on site Or send it to an urban wastewater treatment facility.

Airports are also increasingly beginning to use liquid recovery systems to recycle the glycole and to capture the additives in these liquids, which are sometimes also toxic. You will often use Disprinted areas outside For the frustration of airplanes in order that they will collect and store the liquids after they’ve expired from the plane within the holding of tanks underground until they will be recycled.

Atmospheric icing

During the flight, aircraft use different technologies to alleviate the icing risks. For example, most up-to-date aircraft use Air air systemsChannel the recent air from the compressor of the engine through interior channels to the leading edges of the wings and other critical areas to stop the buildup of ice, while the plane is within the sky.

Some planes also use Electrically heated panels Embedded within the wing of the aircraft to create heat. These control systems cannot normally be used, while the extent is on the ground because they depend on cold air that flows over the surface of the wing. This air flow is frequently reached within the intersection and is vital to stop the world of the aircraft from getting too hot.

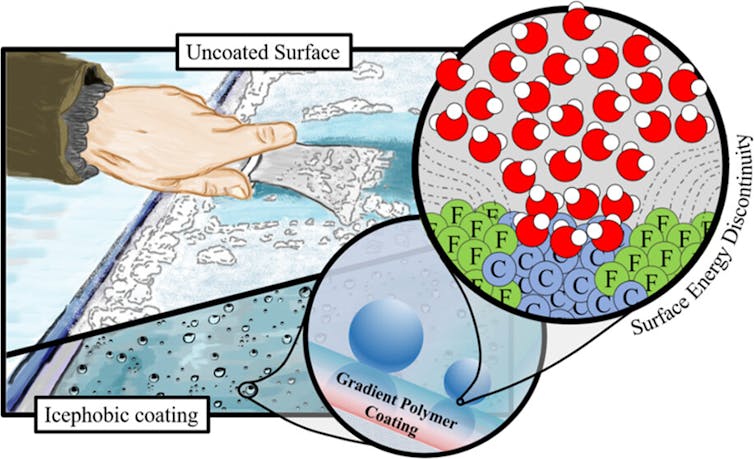

Airlines can sometimes also use Iphobic coatings To prevent latest ice from forming and holding on the outer surfaces of aircraft. These coatings delay how quickly latest ice can form. You may also reduce how much the ice is liable on the surface.

Hernández Rodríguez et al., 2024.Present CC BY-SA

Smaller aircraft may also use Inflatable rubber tires On the wings, known as pneumatic boots, which will be inflated as needed with a purpose to cancel the amassed ice on the front fringe of the wings.

Flying is actually a contemporary scientific miracle. A number of engineering is not going to only get into the bottom, but additionally keep it ice -free in flight. So the following time you experience a weather -related delay on the airport, keep in mind that the bin is required to make sure each a secure and a very uplifting flight.

image credit : theconversation.com

Leave a Reply